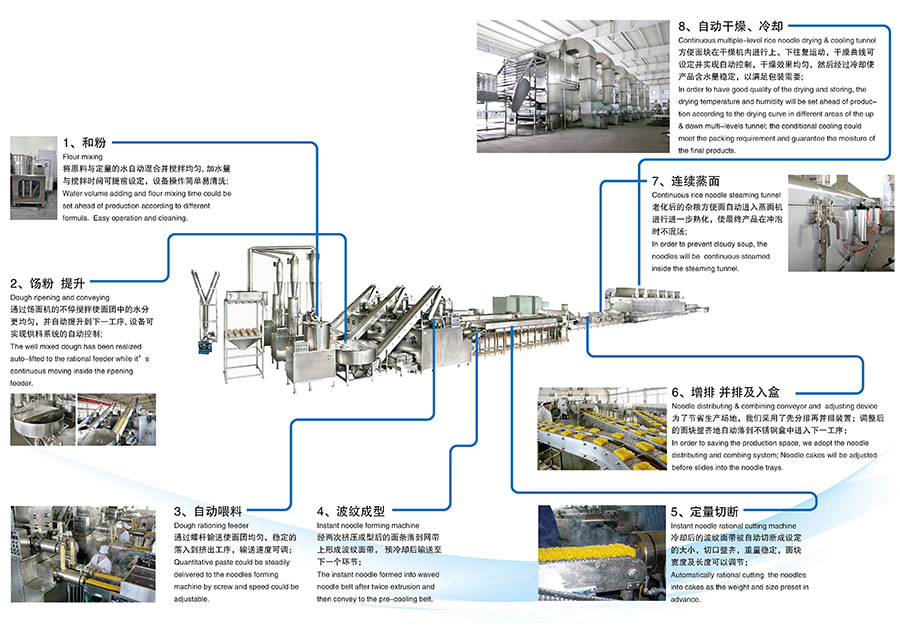

Automatic non-fried extruding instant noodle production line

The series of the automatic non-fried instant noodle production line which is widely used for process grains ramen noodles, such as instant corn noodle, instant soba noodle, instant oats noodle or functionality compound food for special groups. It retains the nature flavor and nutrition of the raw material. It could be served for boiling and cooking with smooth and firm tastes. It achieves three demands for food nutrition, convenience and delicacy.

The production line is mature in technology, reasonable in design, stable and reliable in operation, complete flow in process and diversified scales for different clients requirement not only industrialized enterprise but also small or medium size enterprises.

No. | Model | Output (24hours/ bags) | Daily Capacity (tons) | Dimersion (L*W*H) m | Air Compressed m3/min | Steam Consunption Kg/H | Water Consumption T/day | Operarors each shift | Electricity Power (Kw) |

| 1 | SNTNCS4 | 40000 | 2.8 | 44*2.25*4 | 0.6 | 250 | 2/6 | 7 | 90 |

| 2 | SNTNCS8 | 80000 | 5.8 | 45*2.65*4 | 0.6 | 400 | 3/10 | 7+ | 125 |

| 3 | SNTNCS16 | 160000 | 11.2 | 50*4.5*4 | 0.9 | 700 | 5/15 | 10+ | 235 |

| 4 | SNTNCS24 | 240000 | 16.8 | 60*3.05*4 | 1.2 | 900 | 7/20 | 15+ | 330 |

| 5 | SNTNCS36 | 360000 | 25.2 | 69*3.05*4 | 1.5 | 1200 | 11/30 | 15+ | 451 |

| 6 | SNTNCB4 | 40000 | 2.8 | 44*2.25*4 | 0.6 | 250 | 2/6 | 7 | 90 |

| 7 | SNTNCB8 | 80000 | 5.8 | 45*2.65*4 | 0.6 | 400 | 3/10 | 7+ | 125 |

| 8 | SNTNCB16 | 160000 | 11.2 | 50*4.5*4 | 0.9 | 700 | 5/15 | 10+ | 235 |

| 9 | SNTNCB24 | 240000 | 16.8 | 60*8.05*4 | 1.2 | 900 | 7/20 | 15+ | 330 |

| 10 | SNTNCB36 | 360000 | 25.2 | 69*8.05*4 | 1.5 | 1200 | 11/30 | 15+ | 451 |

Gelatinized slurry will be cooked to a certain temperature is initially cooked by a cooking device.

The gelatinized slurry which is initially cooked by extruder, and then forming into the noodles and which corresponding specifications were produced by extrusion die.

Stainless steel conveyor board„ÄĀblowers and heating devices installed inside the continuous tunnel, a part of moisture could be evaporated by hot wind, make surface of noodle or Ho Fun firm and smooth enough and then easy to be lifted.

After pre-dryingÔľĆthe noodle will be lifted on the rods automatically and then continuously moving into the continuous aging tunnel without cutting.

In order to have better texture in steady quality, the noodle will be aged inside the continuous tunnel, the temperature and moisture could be adjustable according to different products.

According to different form of final products stick type noodle or nest type noodle, the following device of drying and cooling will be required the related equipments.

In order to reach at required water moisture and keep better quality of the final products, the noodle will be transferred into cooling tunnel automatically and lowed down to suitable room temperature for packing. After drying and cooling, the noodle is much more flexible without cracking.

If choose the stick type noodle production, the noodle will be rational cut into required length according neatly; cutting length could be adjustable by PLC.

‚Ď™Each part of whole production line realizes auto-flushing.