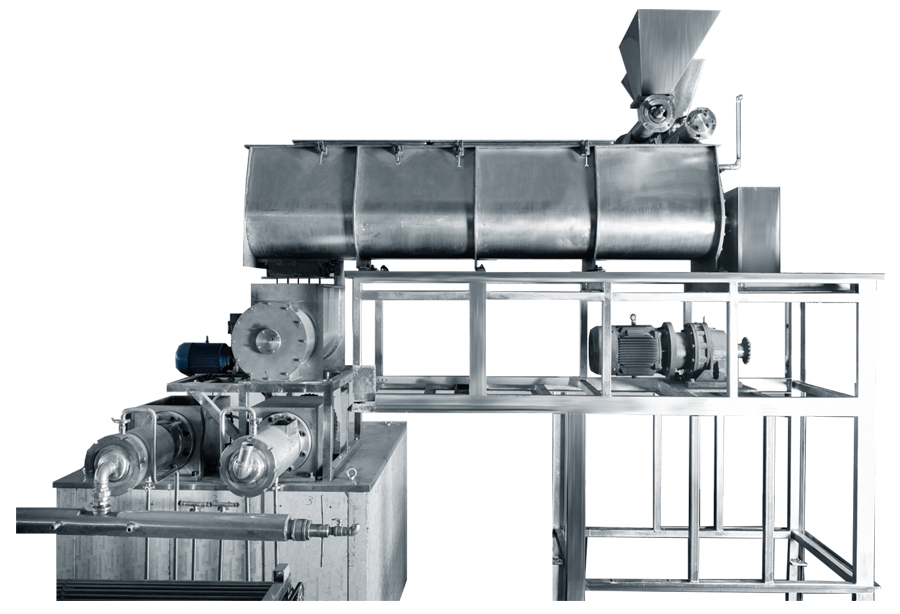

Automatic long cut pasta spaghetti production line

The series of automatic Italian long cut pasta spaghetti production line which adopts the latest continuous closed design from the raw material auto-supplying to the final dried spaghetti production, reduce the food pollution during the whole process and insurance the productsŌĆÖ safety and hygiene.

The series of production line is widely received by its highly automation controlled with simple and maturity process, convenient operation with less use of labor, high qualified rate of products and less production cost.

Main Feature

1.Varity specification for different demands, the capacity from 150 kg to 1000 kg per hour.

2.Closed production design from raw material supplying to the finalproducts with less use of labor, reduce the cost of production.

3.Stable and reliable performance and low failure rate with simple andmaturity process.

4.Scientific and reasonable design for the whole production, qualifiedspare parts and accessories adopt domestic orinternational famousbrand products. At the same time, automatic detection sensors areinstalled in the important process linksof the production line, which canreal-time monitor the work situation and make the product qualitytraceable.

5.All the materials we adopted meet the international food and hygienestandard, the whole machine is made of SUS304stainless steel, theinner wall of extruder sleeve is made of SUS304 stainlesssteel, and the extruder is made of special Alloysteel. Each pipelineadopts fast-connection, easy to disassemble and clean.

6.High automation controlled: the whole linehas gradually replaced traditionalbuttons, temperature control meters,frequency meters, potentiometers and otherelectricalappliances with PLC and touch screen. The man-machine interfaceisused to carry the command issued by the Ethernet switchto realize the exchangeand control of information.

|

NO. |

Model |

Raw material ’╝łT/24hours’╝ē |

Dimension (L*W*H)m |

Compressed Air m3/min |

Steam Consumption Kg/H |

Water Consumption T/day |

Operators each shift |

Electricity Power(Kw) |

| 1 | SNTSV4 |

4 | 35*3.7*3.2 | 88 | ||||

| 2 | SNTSV7 | 7 | 42*3.7*3.2 | 1 | 600 | 4/12 | 5 | 113 |

| 3 | SNTSV15 | 15 | 46*3.5*3.1 | 1.6 | 1000 | 7/20 | 7 | 158 |

| 4 | SNTSV24 | 24 | 61.3.5*3.1 | 170 |

Processing procedure

The pasta could be formed by extruder, the diameter of the die and the shape of pasta could be changed according to the clientŌĆÖs request.

The pasta is ready to be cut after blew out the water of its surface and cooled down by the blowers.

In order to save energy consumption, the temperature and moisture is automatically controlled.

In order to have good quality of the drying and storing, the drying temperature and humidity will be set ahead of production according to the drying curve; The conditional cooling could meet the packing requirement and guarantee the moisture of the final products.