6.Highly automation controlled by subsection and local integration for store, count and monitor of data of process parameters and key quality indicatorsпјҢrealize traceability of product quality.

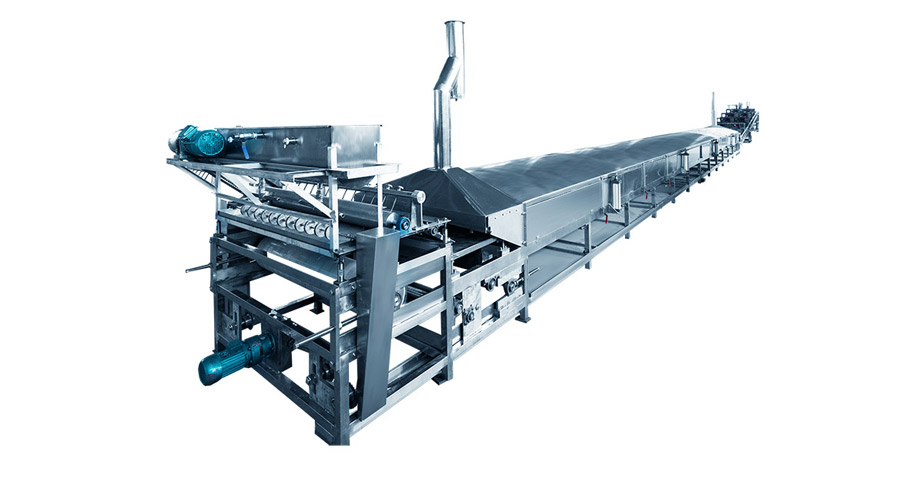

Capacity kg/h | Dimension (L*W*Hпјүm | Steaming consumption Ton/Ton product | Products moisture | Water pressure | Operators Each shift | Electric power |

| 600kg | 50*1.5*1.8 | 0.5 | 63~68 | 0.14Mpa | 7 | 45Kw |

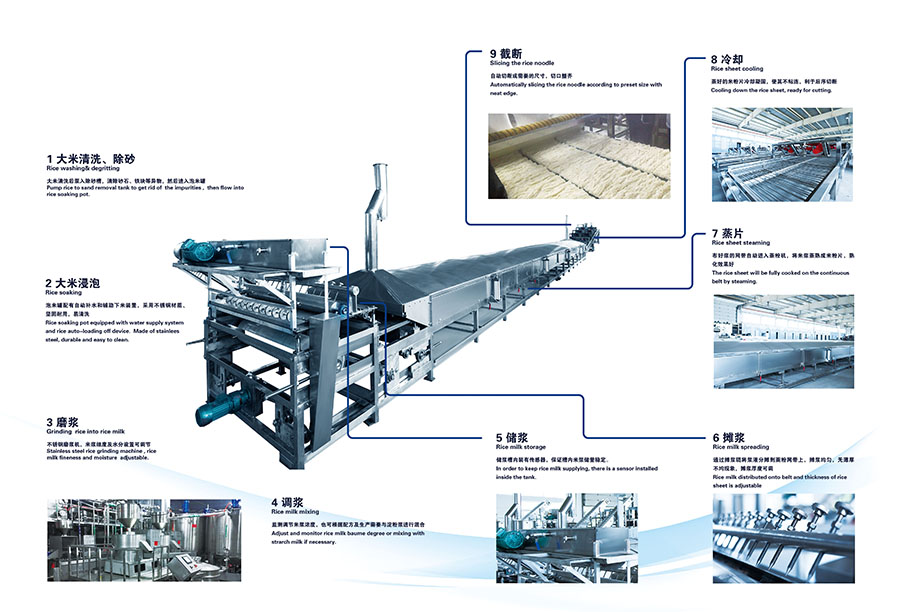

Automatic Fresh Ho Fun sliced rice noodle production line

1. Rice soaking

Rice submerged pumped into stainless steel soaking pot with water supply subsystem and auto-loading off device. Durable and easy to clean.

2. Rice washing & degritting

The rice after soaking is delivered to the sand removal tank for getting rid of the impurities , and then transported into rice washing and draining.

3. Grinding into rice milk

Cleaned rice will be grinding into rice milk by the pulping machine; Fineness and moisture is adjustable.

4.Rice milk filtering & sizing mixing

Rice milk will be filtered and sized out unqualified pellets and then adding starch for adjusting the concentration.

5.Rice milk storage

In order to prevent deposition, the milk will be continuously stirred and balanced inside the storage tank.

6.Rice milk spreading

Rice milk distributed onto belt, and thickness of rice milk is adjustable.

7.Rice sheet steaming

The rice sheet will be fully cooked on the continuous belt by steaming;

8. Rice sheet cooling

Cooling down the rice sheet, ready for cutting

9. Slicing the rice noodle

Automatically slicing the rice noodle according to the data preset before production; the length and width of rice noodle could be adjustable.